PINNACLE EQUIPMENTS PVT. LTD. is a Multi-Product company managed by a group of Technocrat established in 1996. Since then, the company has been in the service to various Chemical, Pharmaceutical, Bulk Drug Manufacturing, Engineering & Mining Industries. We undertake complete Process Design with particular emphasis on Heat Transfer, Distillation, Skid Mounted Piping, Reactors, Pressure Vessels, Storage Tanks, Agitator, Customized Fabrication and Weld overlay. We also undertake design & erection of Piping System in various materials like Stainless steel, Carbon Steel, Duplex & Super Duplex Piping.

We specialize in shop fabricated items with particular emphasis on high-pressure piping, Pressure Vessels & Heat Exchangers and welding of Titanium, Hestalloy. To give you brief overview of our company, we have enclosed an organizational profile outlining among various things, the company's technical capabilities and manufacturing range.

We have a dedicated team of Engineers & Technicians to undertake work at site of structural fabrication & piping. Our teams of technicians, Welders & Fabrication Fitters are very conversant with materials like, Alloy Steel, Duplex, Super Duplex, Stainless Steel, Copper, Cupro Nickel, Hastalloy C & Titanium.

We have long standing experience in heavy mild steel & stainless steel fabrication and have executed jobs under inspection of:-

PINNACLE EQUIPMENTS PVT. LTD. has the expertise, experience & the resources to meet these new challenges with their "state-of-art design, Engineering & manufacturing facilities at Pune apart from strong satisfied Vendors base.

We design & manufacture process equipments to meet the process requirement in accordance with relevant international standards including ASME, TEMA, BS, etc.

PINNACLE EQUIPMENTS PVT. LTD. has the expertise, experience & the resources to meet these new challenges with their “state-of-art design, Engineering & manufacturing facilities at Pune apart from strong satisfied Vendors base.

India is an emerging economy, we in Pinnacle Equipments Pvt. Ltd. Want to have our own share of contribution by adopting the following.

We believe in maintaining precise delivery schedule with unmatched Quality.

| Material Grade | Largest Diameter x Possible Length | Max Thickness | Tonnage |

| Carbon Steel (SA 516 Gr.60/70) | |||

| Shell | Ø 3.50 Meter X up to 12 Meter Long | 30 mm Thk | 30 M Ton |

| Dished End | Ø 3.50 Meter | 30 mm Thk | 2.5 M Ton |

| Tube Sheet | Ø 2.00 Meter | 150 mm Thk | 3.5 M Ton |

| Stainless Steel (SS304/SS316/Duplex/Super Duplex) | |||

| Shell | Ø 3.50 Meter X up to 12 Meter Long | 20 mm Thk | 20 M Ton |

| Dished End | Ø 3.50 Meter | 20 mm Thk | 2 M Ton |

| Tube Sheet | Ø 2.00 Meter | 150 mm Thk | 3.5 M Ton |

| Material Grade | Largest Diameter | Max Thickness | Tonnage |

| Dishing | |||

| Dished End (SS) | Ø 3.50 Meter | 20 mm Thk | 2 M Ton |

| Dished End (CS) | Ø 3.50 Meter | 30 mm Thk | 2.5 M Ton |

| Rolling | |||

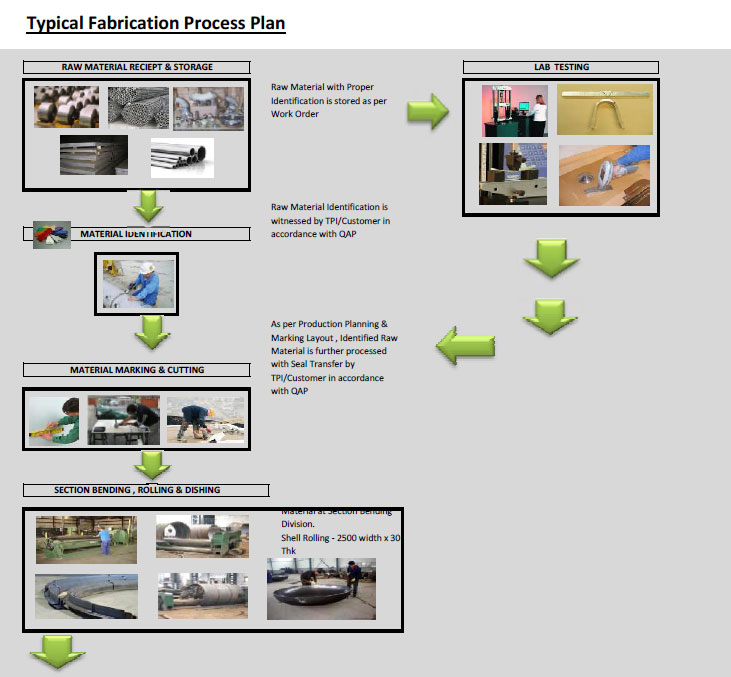

| SS | Width 2500 | 20 mm Thk | |

| CS | Width 2500 | 30 mm Thk | |

| Bending | |||

| SS | Width 2000 | 10 mm Thk | |

| CS | Width 2000 | 12 mm Thk | |

| Drilling | Max Hole Dia 50 mm x 170 Deep | ||

| Digital Tube Expansion with Torque Controller |

Available up to 38.1 OD | ||

| FACILITY | NAME OF MACHINE | CAPACITY | QTY. | MAKE OF MACHINE |

| CLEANING & PAINTING | Pneumatically Operated Painting System Compressor Compressor Spray Guns |

5 Hp. 3 Hp. 5 Ltrs |

2 No. 1 No. 1 No. 5 Nos |

Kirloskar Make Aromatic Equip. Co. |

| MATERIAL HANDLING | Overhead Crane Chain Pulley Block Chain Pulley Block Pulling Tackles Mobile Crane (On Hire basis) Mobile Crane (On Hire basis) |

10 Ton 5 Ton 2 Ton 2 Ton 12 Ton 14 Ton |

1 No. 1 No. 1 No. 1 No. 5 Nos. 5 Nos. |

Indef Escort / JCB Escort / JCB |

| PLATE BENDING & ROLLING |

Plate Bending Machine 2000 width Double pre-pinch type 30mm thk. X 2500 mm heavy duty plate bending machine |

Up to 4 mm Thk 30 mm in Thk |

1 No. 1 No. |

|

| PIPE BENDING | Hydraulic Operated Pipe bending | Up to 50 NB x sch 80 Pipe |

1 No. | Custom Built |

| FACILITY | NAME OF MACHINE | CAPACITY | QTY. | MAKE OF MACHINE |

| DISHING | Hydraulic Operated Point Press | Max Dia 3.5Mtrs x 30 Thk |

1 Nos. | Custom Built |

| TUBE EXPANDING & GROOVING |

Digital Tube Expander With Torque Controller Double Grooving Tool for Internal Grooving |

up to 38.1 OD Tube sizes |

1 Set | Power Master |

| MEASURING INSTRUMENT |

Vernier Calipers Vernier Calipers Micro meter Steel Tape Steel Tape Measuring Tape Measuring Tape |

0-200 mm 0-600 mm 0-25 mm 0-3 Mtrs 0-5 Mtrs 0-15 Mtrs 0-30 Mtrs |

3 Nos. 3 Nos. 2 Nos. 5 Nos. 5 Nos. 2 Nos. 2 Nos. |

Mitutoyo Mitutoyo Mitutoyo Freemans Freemans Freemans Freemans |

| HYDROSTATIC PRESSURE TESTING |

Motorized Hydraulic Testing Pump Hand Pump |

Up to 100 kg Up to 25 kg |

1 Nos. 3 Nos. |

C Bole Valton India |

| FACILITY | NAME OF MACHINE | CAPACITY | QTY. | MAKE OF MACHINE |

| NON DESTRUCTIVE | Radiography: Complete facility Densitometer, optical micrometer (L.C.0.1mm) Penetrameter DIN/ATSM All these facilities are available locally. Ultrasonic Testing: Digital Ultrasonic thickness measuring gauge, ultrasonic flaw detector with probe. Helium Leak Test: |

Out Sourced at NABL approved Testing Facilities |

||

| HEAT TREATMENT | Approved by "Director Of Steam Boilers, Mumbai Complete Facility with Electric Surface Heating & Controls, Oil/Gas Fired Furnaces, Heat Treatment Equipments, Onsite Pre& Post Weld Heat Treatment, High Velocity Ladle dryers & Pre-Heaters is available. |

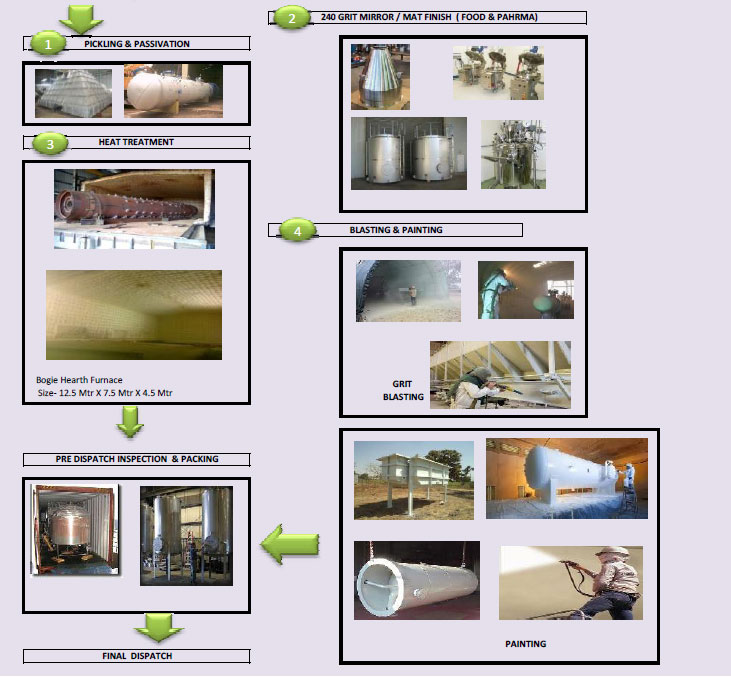

Bogie Hearth Furnace Size 12.5 Mtr x 7.5 Mtr x 4.5 Mtrs |

1 No. | Out Sourced |

| BLASTING & PAINTING | Closed Blasting & Painting Booth is equipped with Fully atomized Spray Gun System |

10 Mtr x 20 Mtr x 12 mtrs |

1 No | Out Sourced |

|

|

|

|

Follow Us On With